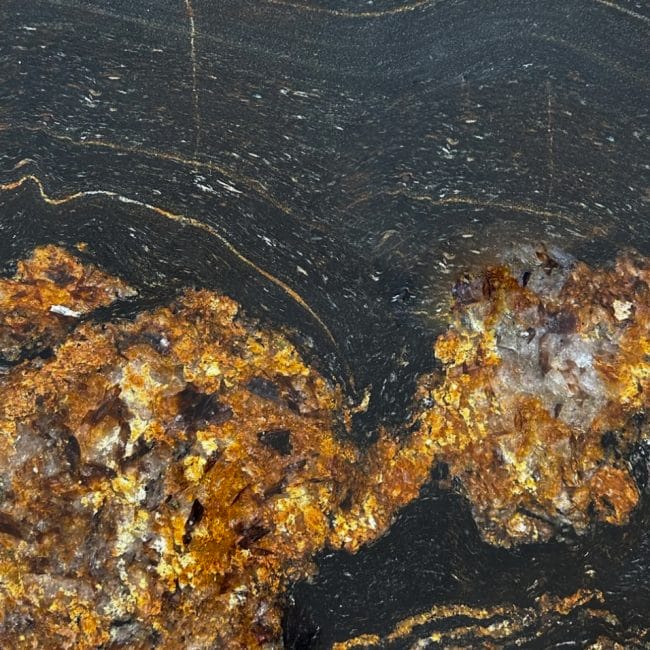

METALS

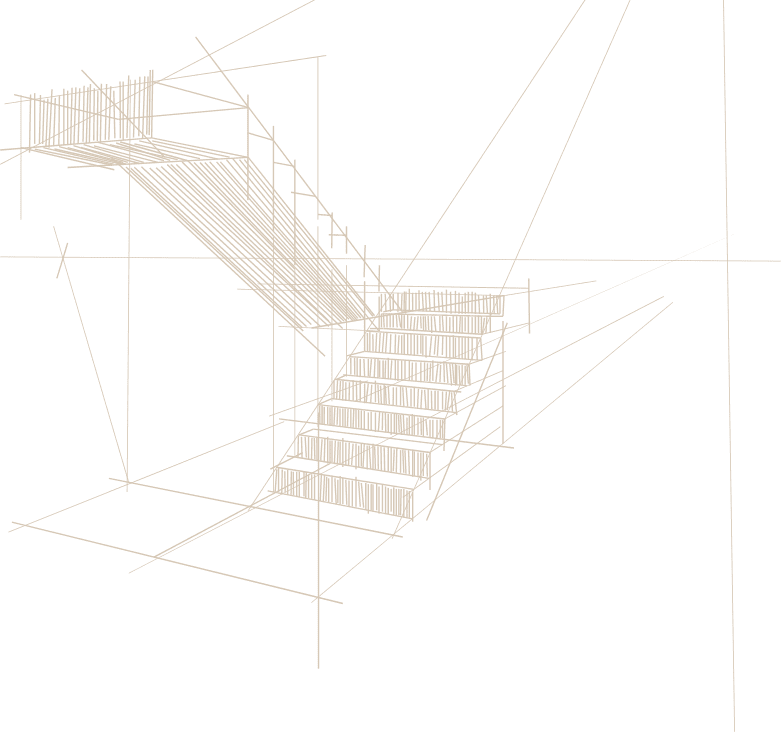

Metal is a foundational element in staircase construction, prized for its strength, durability, and versatile aesthetic appeal. Utilized in everything from sleek modern designs to ornate traditional settings, metal can shape the very character of a staircase, influencing both its functionality and its interaction with the surrounding space. The choice of metal in a staircase design directly affects the structure’s resilience, maintenance requirements, and overall cost-effectiveness, making it a critical consideration for architects and builders alike.

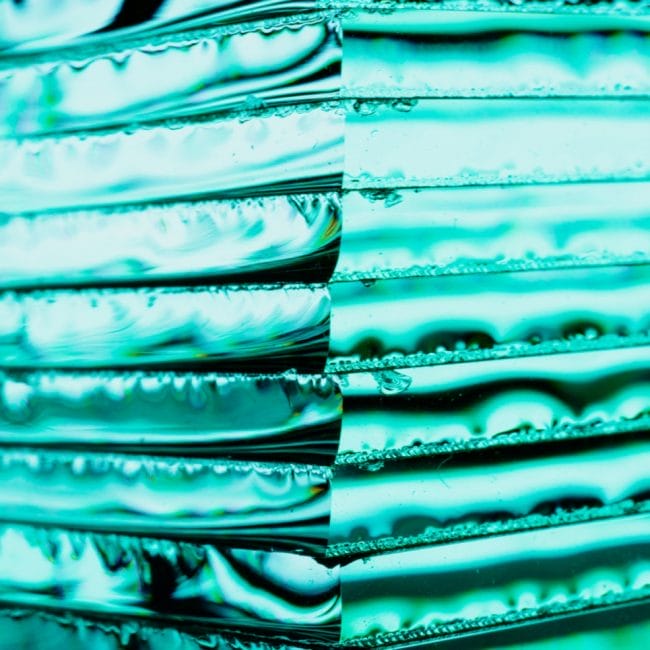

APPEREANCE UPLIFT

In staircase applications, metal is often favored for its ability to provide robust support while maintaining elegance and style. Its inherent strength allows for slimmer profiles and more expansive designs, which can help maximize space and enhance natural light flow within a building. Moreover, metal’s adaptability in terms of finishes—from brushed to polished or even painted—enables designers to tailor the staircase to fit any interior theme or color scheme. Whether used as a main structural component or as a subtle accent in balustrades and handrails, metal brings a unique blend of functionality and design sophistication to staircases, proving why it remains a popular choice among construction materials.

VERSATILE

Mild Steel: Known for its versatility and affordability, mild steel is a popular choice for a wide range of structural and decorative applications. It offers good strength and machinability, making it suitable for various fabrication processes.

Stainless Steel: Recognized for its sleek appearance and exceptional corrosion resistance, stainless steel is ideal for applications requiring hygiene, durability, and aesthetic appeal. It’s commonly used in modern architectural designs, especially in environments exposed to moisture or harsh conditions.

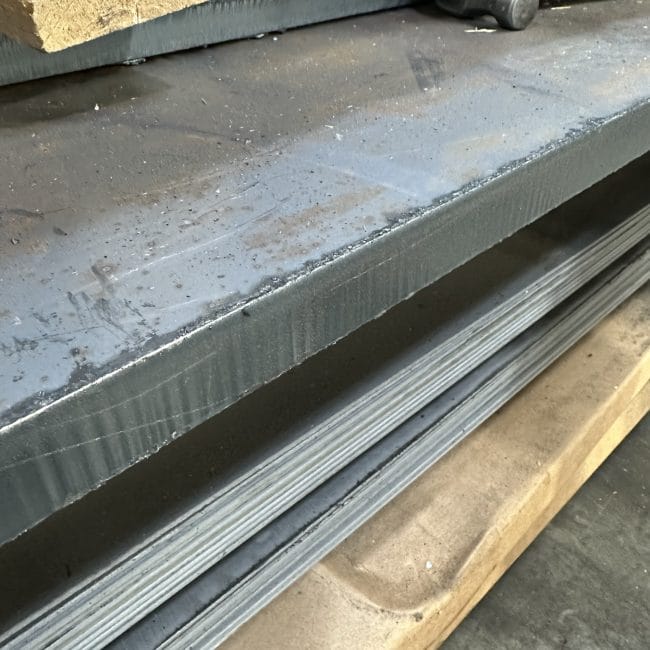

HIGHLY DURABLE

Carbon Steel: Offering high strength and toughness, carbon steel is widely used in structural and industrial applications. Its versatility and cost-effectiveness make it suitable for a broad range of projects, from construction to machinery manufacturing.

Alloy Steel: Engineered to exhibit enhanced mechanical properties, alloy steel combines the strength of carbon steel with additional alloying elements such as chromium, nickel, or molybdenum. This results in improved hardness, toughness, and wear resistance, making it suitable for demanding applications in automotive, aerospace, and machinery industries.

REGGED RELIABILITY

Cast Iron: Renowned for its exceptional durability and heat resistance, cast iron is often used in heavy-duty applications such as machinery components, engine blocks, and cookware.

Galvanized Steel: Treated with a protective layer of zinc to prevent corrosion, galvanized steel offers superior durability and longevity, particularly in outdoor environments. Its rugged reliability and resistance to rust make it suitable for a wide range of construction and infrastructure projects.

Wrought Iron: Known for its timeless elegance and wrought texture, wrought iron is a classic choice for ornamental railings, gates, and architectural accents.

01. What are the different types of steel commonly used in construction and design?

Common types of steel used in staircase construction include mild steel, stainless steel, carbon steel, alloy steel, and cast iron.

02.How do I choose the right type of steel for my project?

Select the right steel for staircases based on factors such as required strength, corrosion resistance, aesthetics, and budget constraints, consulting with staircase designers or engineers as needed.

03. What are the key factors to consider when selecting steel for indoor versus outdoor applications?

For outdoor staircase applications, prioritize corrosion resistance, weatherability, and durability, while considering appearance and maintenance requirements for indoor staircases.

04. How does the strength and durability of different types of steel vary, and what factors affect their longevity?

Strength, durability, and longevity vary among steel types, influenced by factors like composition, treatment, and exposure to environmental elements.

05. What are the advantages of using steel over other materials in construction and design?

Steel offers advantages for staircase construction, including high strength-to-weight ratio, versatility in design, durability, and aesthetic appeal.

06. How can I ensure the sustainability of the steel used in my project?

Ensure steel sustainability in staircase construction through responsible sourcing, material efficiency, and promoting recycling and reuse.

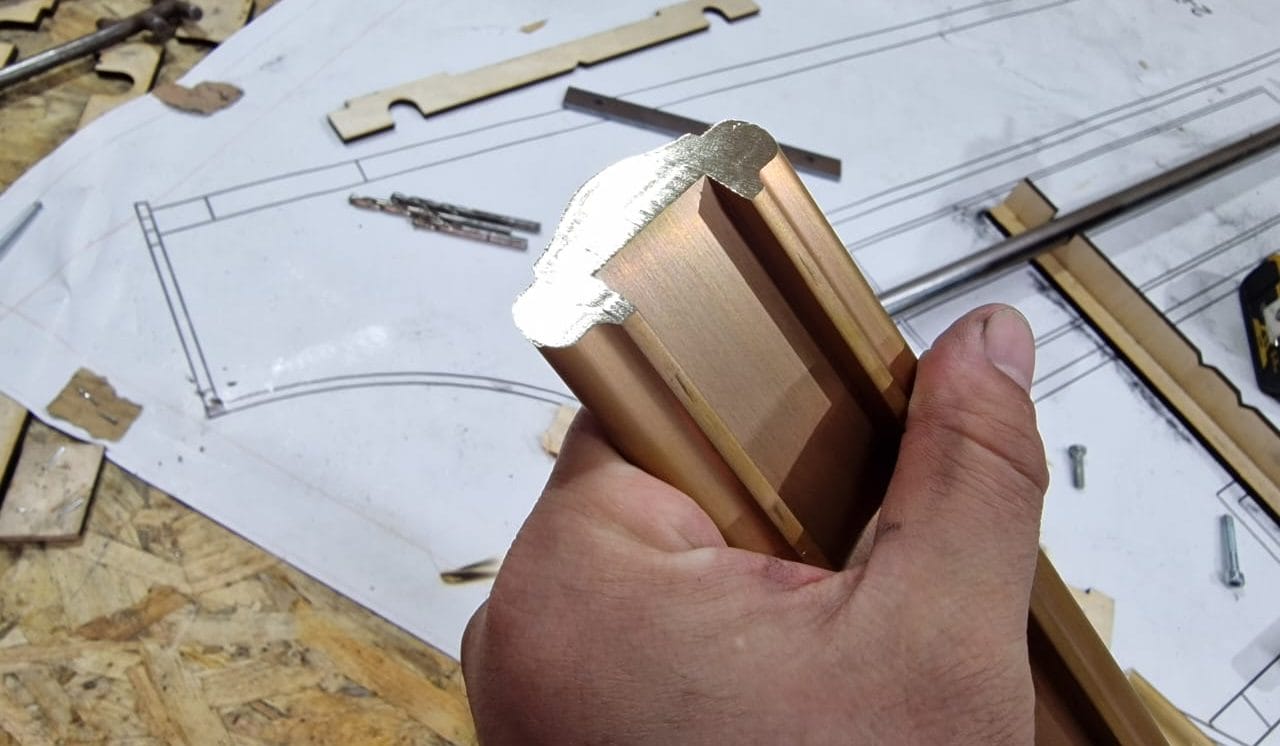

07. What are the common finishes available for steel surfaces, and how do they affect appearance and maintenance?

Common finishes for steel staircase components include polished, brushed, galvanized, and powder-coated, each impacting appearance, texture, and durability.

08. Are there any specific installation techniques or considerations for different types of steel?

Different steel types may require specific installation techniques and considerations for staircase fabrication and assembly to ensure structural integrity and safety.

09. What are the typical maintenance requirements for steel surfaces, and how can I keep them looking their best?

Regular maintenance of steel staircase components involves cleaning, inspection for corrosion or damage, and applying protective coatings as needed to maintain appearance and performance.

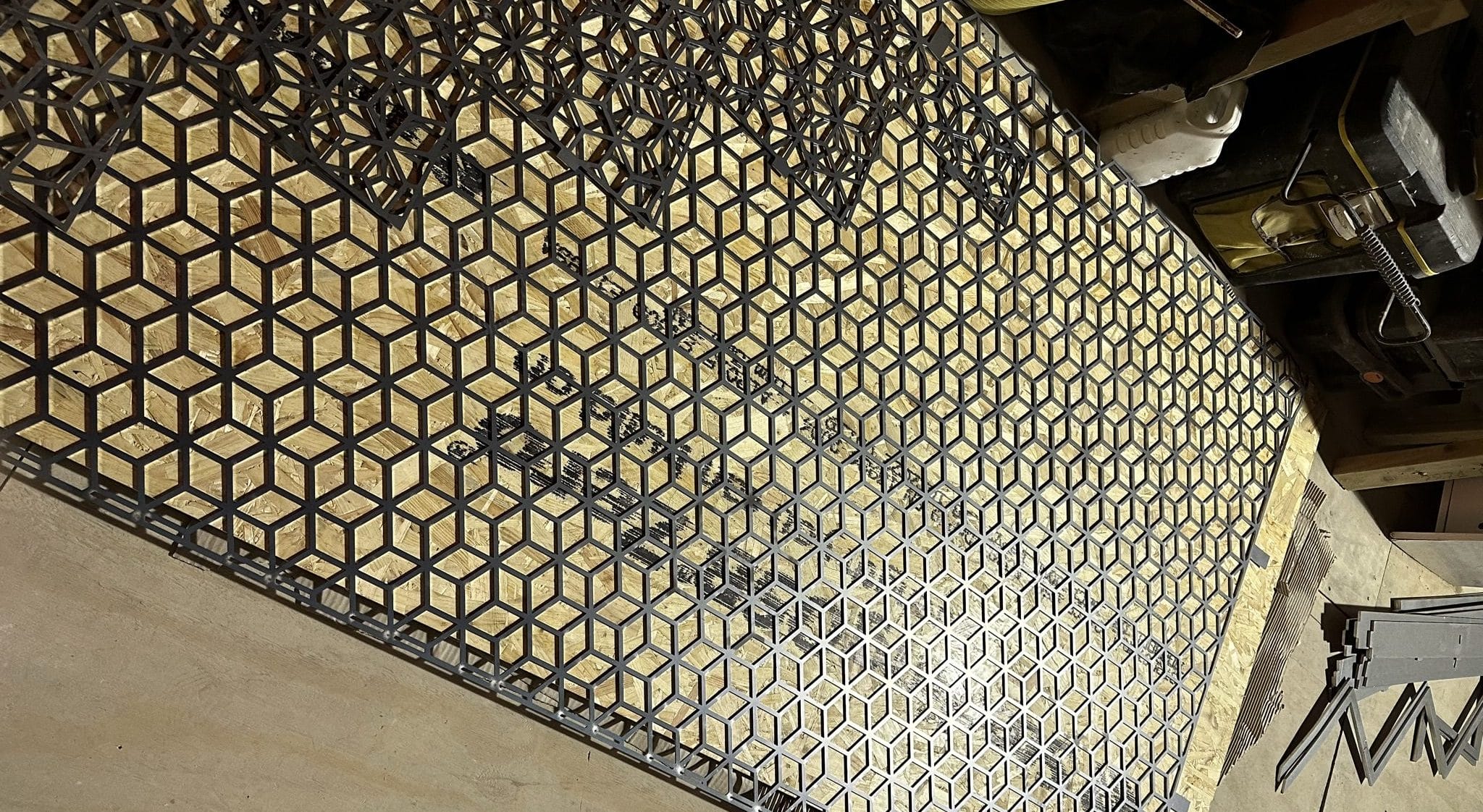

10. Can steel be used in creative or unconventional ways in design, and what innovative applications are possible?

Steel can be creatively incorporated into staircase design, offering opportunities for innovative balustrade designs, artistic detailing, and structural elegance in architectural expression.

customer service support

V.P STAIRS

A: The Barn, 100 Cecil Street, Watford, WD24 5AP

T: 07418 315550

C: VAT Number GB 386512281

H: Monday to Friday 8:00 AM to 6:00 PM