Common Mistakes in Staircase Planning

Some people who want to save money wonder if they can build a staircase themselves. Theoretically, yes, but in practice, you will need your own team, as it is a complex process. Even when working with a leading staircase installation company in the UK, you will need to think about some things carefully. Underestimating the importance of the entire process can lead to serious mistakes even in the early stages.

Even experienced builders make some mistakes. They can be very costly, so it is better to take care of preventing or eliminating them in advance. That is why in this article we have compiled a list of common mistakes that are made in the early stages of planning the construction and installation of staircases.

What Can Early Mistakes Lead To?

On the one hand, mistakes in the early stages are not critical, as they can be quickly corrected. Conversely, they can cause serious issues if forgotten or ignored. Here is some more information about what common mistakes in the early stages can lead to in the context of staircase construction:

- Safety hazards and injuries. Poor rise going ratios, inadequate headroom, or non-compliant guarding increase trip risks and falls.

- Costly rework and delays. Incorrect layouts or structural allowances (stringers, openings, supports) trigger demolition, new fabrication, and programme slippage.

- Regulatory non-compliance. Misjudged widths, landings, or balustrade heights can cause redesign, rework, and possible fines.

Want to see a real-life example? Imagine that you initially chose the wrong materials during the planning stage. If you underestimate this problem, you will ultimately have to rebuild the structure. This can result in significant financial costs.

Top 5 Mistakes You Should Know About

As you may have already realised, this task requires careful planning and understanding of many matters. That is why many silly mistakes are made in the early days (especially by beginners). In this article, we have compiled what we believe to be the five most common mistakes in planning staircase projects.

We recommend learning more about the necessary terms related to staircases before starting construction → https://vpstairs.com/10-terms-to-know-before-buying-a-staircase/

1. Lack of a Clear Step-by-Step Plan

Undoubtedly, it all starts with clear planning and understanding what to do and when. First of all, you need to decide on your ideas. This is a common problem we see among our customers. For example, when a husband and wife have different points of view, it is difficult for them to come to a final decision on the staircase design.

Once the idea has been approved, it is worth moving on to planning the position of the structure in the room. Then the materials, stairs, style of construction, shape and other important parameters are selected. Learn more about the necessary steps for planning a bespoke staircase to avoid costly mistakes once work has begun!

2. Choosing Unsuitable Materials

Materials set the tone, durability and safety of a stair. Select the wrong species, alloy or composite and you invite warping, squeaks, delamination and slippery treads. Woods to the site’s humidity move and crack. Polished stone without anti-slip treatment becomes hazardous when wet. Fire rating, acoustic transmission and maintenance burden are also tied to material choice. When comparing staircase materials, look beyond upfront price to whole-life cost and compliance.

Common pitfalls include mixing incompatible finishes, ignoring fixings and tolerances, and choosing products that lack test data. A resin that off-gasses can breach indoor-air requirements; glass without laminated interlayers can fail under point load. Verify slip-resistance (PTV), reaction-to-fire class and warranty coverage.

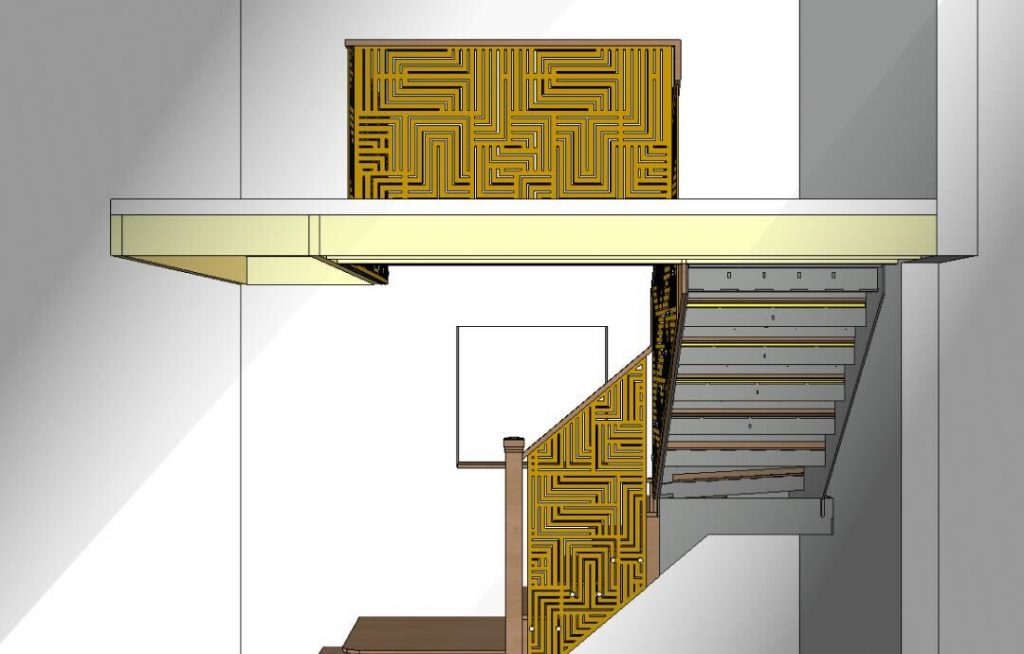

3. Improper Measurements at the Facility

Measurement errors cascade through every decision. Misstated floor-to-floor heights distort rise/going proportions and create non-compliant pitches. Under-measured stairwell openings cause headroom infringements. Forgetting finished floor build-ups (underlay, screed, tiles) skews calculations by 10-40 mm. Out-of-plumb walls and uneven substrates shift stringer lines, while unrecorded beams, ducts and door swings trigger site clashes. The result is rework, delays and uncomfortable, unsafe stairs.

4. Underestimating Security Issues

Common risks arise from steep pitches, inconsistent rises, shallow goings and inadequate headroom. Missing or poorly placed handrails, weak fixings and balustrades with over-wide gaps expose users to falls (especially children and the elderly). Low-friction surfaces, unmarked nosings and poor lighting increase slip risk. Fire considerations are often overlooked: protected routes, landing widths and door clearances must remain unobstructed under load and smoke conditions.

Treat safety as a primary requirement. Design to relevant regulations and guidance from the outset, validating riser/going ratios, guarding heights and loadings. Specify proven anti-slip finishes and nosing contrast. Integrate continuous lighting and reliable power.

5. Non-compliance with Building Standards

The last mistake we would like to tell you about in more detail is ignoring building regulations. You cannot build the way you want, because people’s safety depends on it. Moreover, when it comes to public properties (boutiques, restaurants, medical clinics, etc.), you must strictly follow the BS 5395-1:2010 standard. This document contains requirements and recommendations for the construction of stairs in the United Kingdom. For example, the height of the handrail must be between 900 and 1000 mm, both in private and public projects.

Discover the current building regulations for staircases in the UK!

How to Avoid Common Mistakes When Designing a Staircase?

The most effective way to prevent design missteps and costly rework is to involve specialists from day one. Early collaboration means your stair’s geometry, structure, materials and compliance are resolved together. And here are some of our benefits:

- We conduct a detailed analysis and survey before design to eliminate dimensional risk and headroom clashes.

- We specify certified materials with proven slip-resistance, fire performance and durability, complete with test data and samples.

- We provide transparent costs and programme with value-engineered options, clear lead times and risk registers.

To minimize errors, freeze key dimensions after the survey, approve samples, and conduct formal design reviews at each stage. Maintain a single source of truth for drawings and revisions, and never bypass site checks before fabrication.

V.PSTAIRS – Always Available to Assist You

Questions, sketches, or a tricky site condition? Partnering with V.PSTAIRS from the start gives you a compliant, comfortable staircase. You’ll speak with engineers and makers who give straight answers, clear options and practical next steps. Ready to de-risk your staircase and avoid costly rework? Get your free consultation today by contacting us in any convenient way for you!