How to Save on Staircases Without Sacrificing Quality?

When it comes time to install a new staircase or renovate old construction, many homeowners look for ways to save money. This is actually quite a normal situation. The most important thing is not to save money in a way that negatively affects the final result. Moreover, there are many ways to reduce the overall cost of the project without sacrificing the quality of the structure at all.

What should you do? Surely, the first thing to consider is the staircase materials, as this is one of the main factors affecting the final cost. Based on our experience, we would like to tell you about the best ways to reduce the cost of your staircase while maintaining functionality, safety, and aesthetics at the highest level. Here we go!

Why Shouldn’t You Sacrifice Quality for Cost?

Cutting corners on a staircase is a false economy. Why is it so? It’s a load-bearing, high-traffic, safety-critical element that must feel solid underfoot for decades. Inferior timber grading, weak fixings, sloppy joinery, and out-of-tolerance geometry (rise/going) lead to flex, wobbles, and premature wear. Beyond day-to-day irritation, poor quality can trigger failures in inspections, invalidate warranties, and create a real risk of injury, claims, and costly remedial work.

- Structural risk. Under-spec stringers, treads, or fixings can loosen, sag, or crack.

- Hidden lifecycle costs. Re-leveling, re-fixing, and repainting quickly erase any upfront “savings”.

- Noise and movement. Creaks and deflection signal stress that shortens service life.

- Poor fit and finish. Gaps, splinters, and rough edges harm both usability and appearance.

Quality pays for itself through accurate geometry, durable materials, and proper installation that keep the staircase tight, quiet, and safe. If you must economise, do it smartly.

1. Choose Affordable But Yet High-Quality Materials

You don’t need premium oak everywhere to achieve a robust, handsome staircase. Use cost-effective cores and save the budget for the parts you touch and see. Engineered options like LVL or laminated softwood for stringers and plywood treads with a solid hardwood nosing. They can offer stability and strength at a lower price than full-depth hardwood. For enclosed stairs, paint-grade risers and stringers (pre-primed MDF/softwood) paired with hardwood handrails and caps give a high-end look without the high-end bill.

Focus on specification, not just species. Pick C24-graded softwood or equivalent, check moisture content, and buy components that are straight, knot-controlled, and warrantied. Finger-jointed, pre-primed pine is perfectly acceptable if it’s properly rated; it paints beautifully and reduces waste. Standardise profiles (treads, handrails, spindles) so replacements are easy and cheap. Finally, select finishes that work hard: durable lacquer for hardwood, quality undercoat, and enamel for paint-grade parts. This protects the timber and cuts future maintenance costs.

Explore the best types of wood for a staircase in our article → https://vpstairs.com/best-types-of-wood-for-staircases-personal-experience-of-v-pstairs/

2. Don’t Focus on Complex Constructions

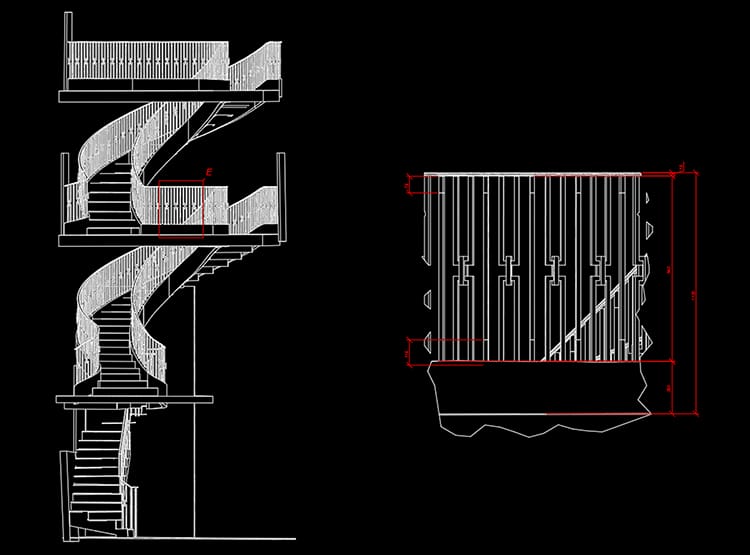

Complex geometry drives cost. Curves, cut strings, open risers, and mixed materials multiply labour, jigging, and site time. A straight flight or a simple quarter-turn with a landing usually delivers the best value. Fewer bespoke templates, faster installation, easier compliance, and neater interfaces with floors and walls. Closed-string staircases are typically cheaper and quieter than cut-string, and standard balustrade systems assemble quickly with consistent results.

Value lives in simplicity and repetition. Keep to standard rises/goings, choose off-the-shelf newels, and avoid heavy glass or intricate metalwork unless it’s mission-critical to the design. If you want a visual lift without the price spike, use clean detailing like square-edged treads, uniform spindles, and a slim handrail profile. Prefabricated or modular flights can further reduce cost and onsite disruption while maintaining rigidity and alignment, provided measurements are accurate and the substrate is sound.

3. Avoid Common Mistakes

Most overspend comes from rework, not materials. So, don’t order before a final site measure. Small deviations in floor levels, wall plumb or opening widths force on-site alterations and extra visits. Avoid under-spec fixings and adhesives.

Skimping on the balustrade is another trap. Handrails, newels and spindles are safety-critical; mixing incompatible systems or ignoring manufacturer centres causes wobble and failed inspections. Plan service routes (heating pipes, wiring) and nosing clearances before cutting; unplanned notches or trims weaken components. Finally, choose an installer with proven staircase experience, ask for method statements, and insist on a sequence that includes adhesive bonding, proper screw patterns and snagging.

4. Collaborate with Experienced Professionals

Many people may find it tempting to start working with novice specialists or even choose a DIY approach. However, practice shows that these are not the best solutions. You may think that beginners offer lower prices compared to experienced experts.

This is not entirely true, since most of the cost is determined by your decisions: the materials you choose, the type of staircase, the finish and the total construction area. On the contrary, when working with dubious builders, you may encounter poor-quality work and no guarantee. Ultimately, you will have to rehire specialists and overpay.

Discover the main reasons you should turn to experts to create a staircase here → https://vpstairs.com/the-main-reasons-you-should-turn-to-experts-to-create-a-staircase/

Where to Order Custom Staircase Construction Services in the UK?

Some people underestimate the benefits of turnkey staircase building in the UK, and this is a fatal mistake. Why is that? You don’t need to look for several contractors and work with designers, architects and professional builders at the same time. The best solution is to find a leading staircase supplier in the UK, which will save you a lot of trouble.

For example, at V.PSTAIRS, we provide unique staircase design and installation services throughout the UK. This means you get all the services you need in one place, without having to pay extra. One contract, one supplier and the best result. Here you can choose what suits your preferences and budget. Any materials, types of construction and additional solutions. Would you like to book a free consultation? Simply contact us in any convenient way, including:

- Our website by filling out the form.

- Email: hello@vpstairs.com.

- Tel: +44 7418 315550.

We will provide feedback as soon as possible. Our managers will analyse your request and offer the best solution for your case, which fits your expected budget!

1 Comment

Comments are closed.

Lucy Morgan

This is the first save money article that doesn’t scream “cheap it all out”. The whole-life cost point is real because refinishing/repairs add up…